Level 1: BOM Setup

The BOM Setup page enables you to configure the product to be manufactured, materials needed to manufacture (in terms of unit of measure, quantity and warehouses), machines to be used, stages that complete the manufacturing process, other expenses directly or indirectly related in manufacturing the product, and the by-product or secondary product produced from a manufacturing process.

Fields at the top of the form

1. The BOM Setup Number will be automatically filled in with a unique number based on the starting number that is assigned in the Starting Numbers form > Manufacturing. This number is used as a reference for you and VisionCore to help find this transaction later if necessary. It can be manually changed on this form as long as it does not duplicate a previous BOM Setup Number.

2. The Finished Goods Warehouse is where you can set the warehouse where finished goods/products go to.

3. The Product ID field will show all items that are set as manufacturing type. In this field, select the main or primary item you would want to manufacture.

4. The Description field will automatically display the item's description entered in the Inventory form though you can modify this if you need to.

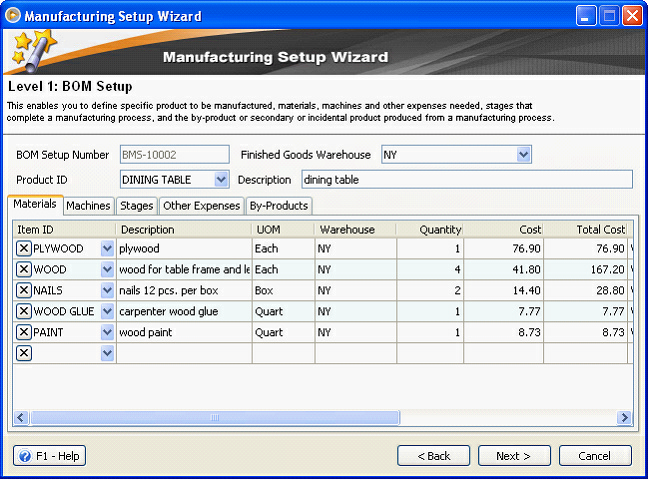

Material Setup

In the Material tab enter raw materials needed for manufacturing the main product in terms of unit of measure, warehouses and quantity.

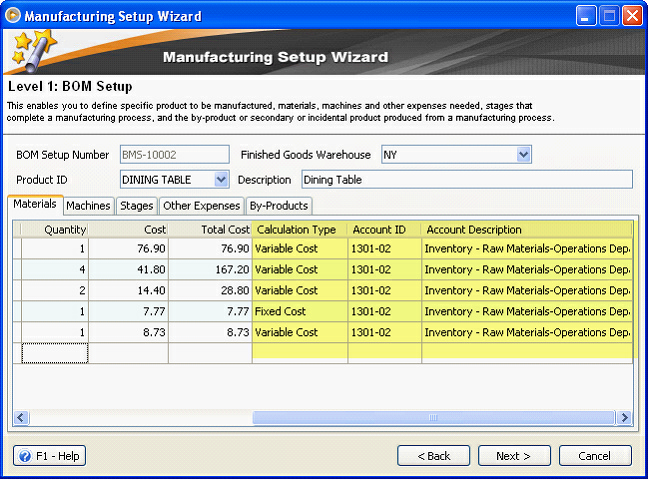

Use the scroll bar to configure the Calculation Type and Inventory Account ID.

Options for Calculation Item Type:

![]() Fixed Cost - Product's cost that does not change in quantity even if the number of products manufactured increases or decreases

Fixed Cost - Product's cost that does not change in quantity even if the number of products manufactured increases or decreases

![]() Variable cost - Product's cost that changes in quantity depending on the number of products manufactured.

Variable cost - Product's cost that changes in quantity depending on the number of products manufactured.

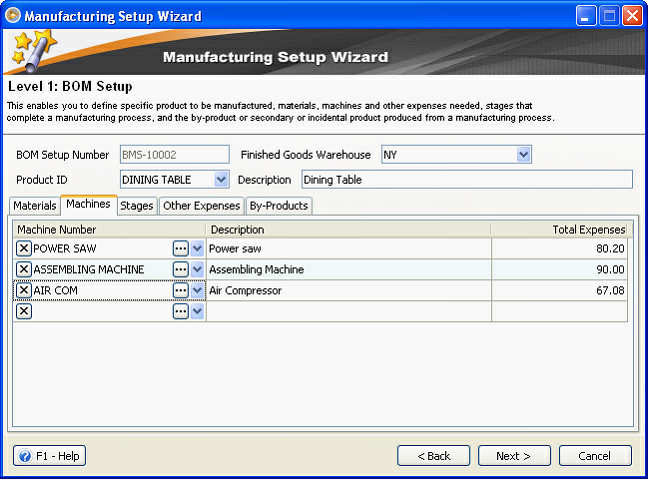

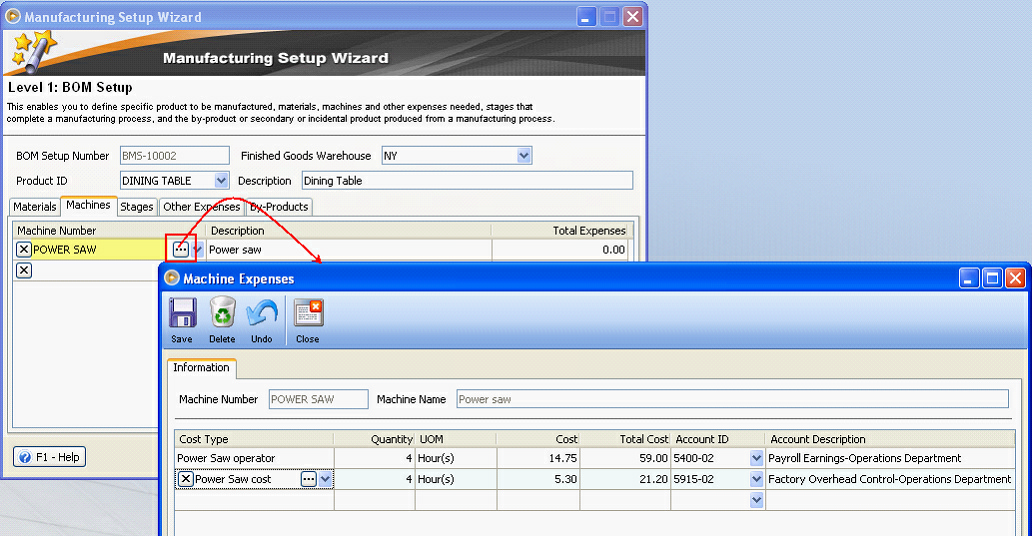

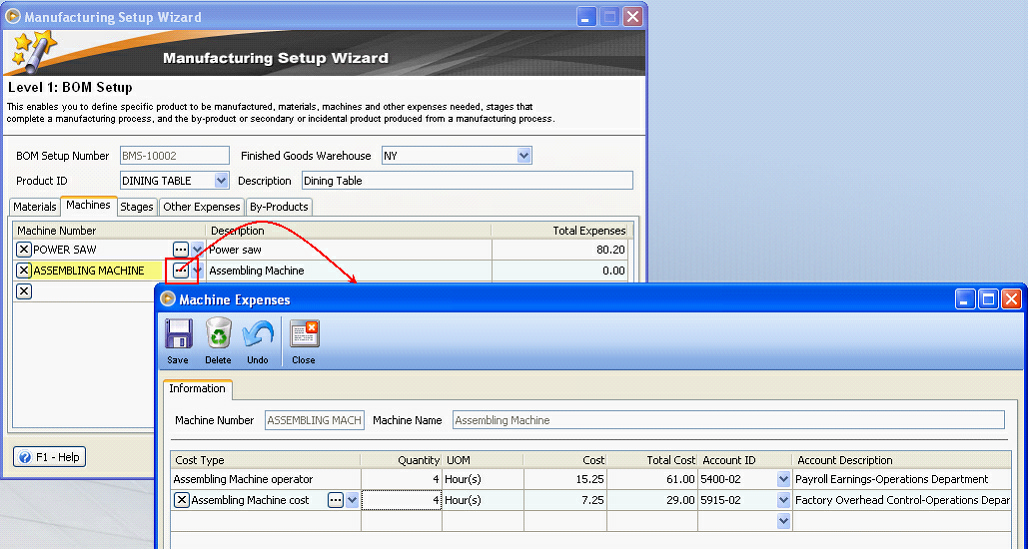

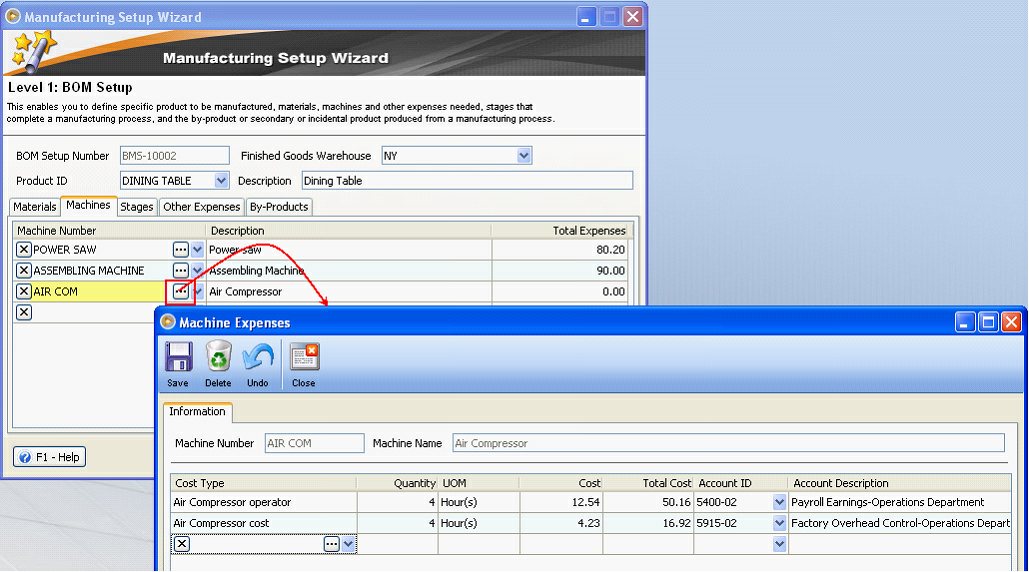

Machine Setup

This Machine tab is used to enter machines needed for manufacturing, machine costs and other costs related to machines.

How machines and machine costs are setup:

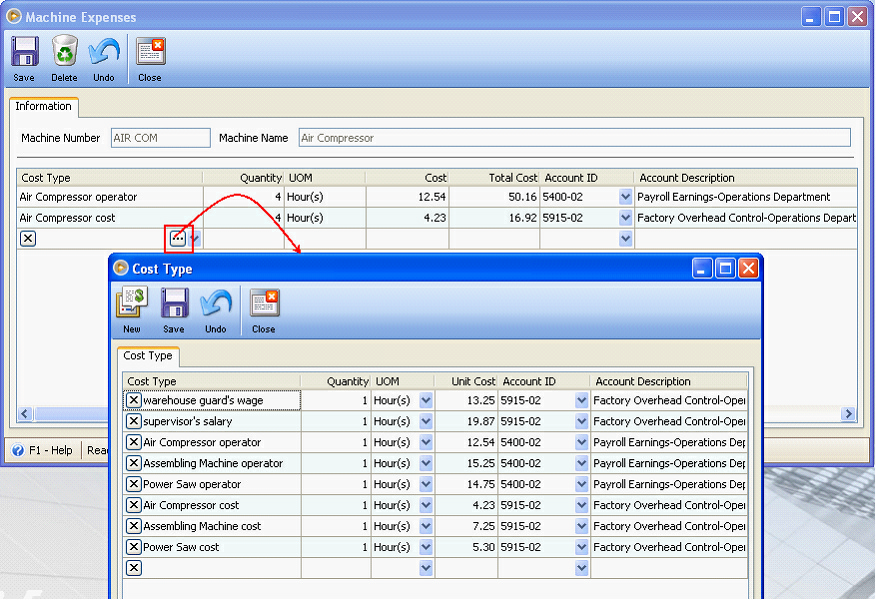

Click the ellipse button on Cost type field to open the Cost Type form where you can add other cost types.

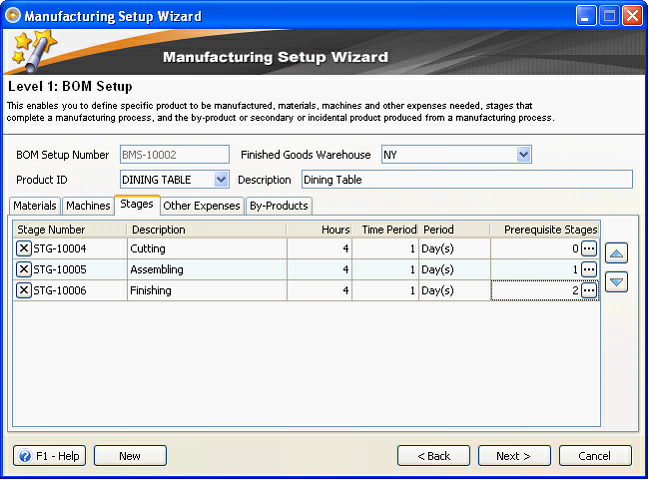

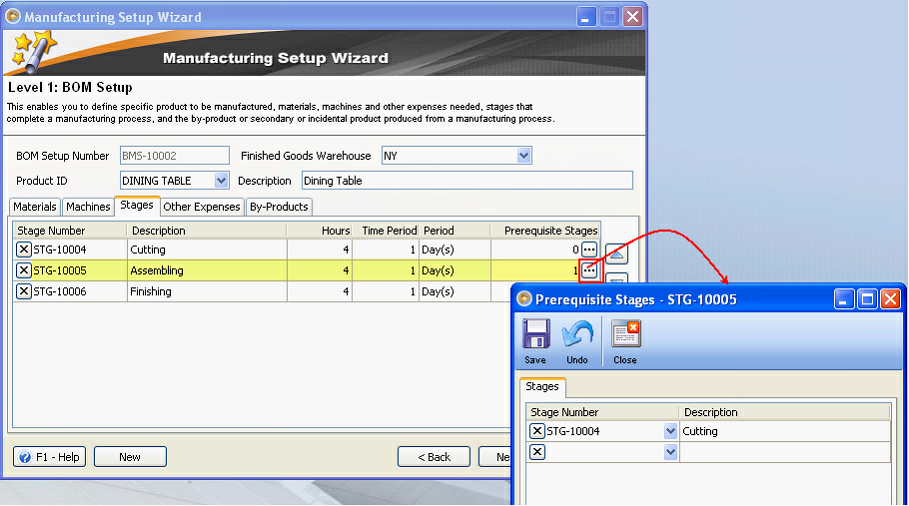

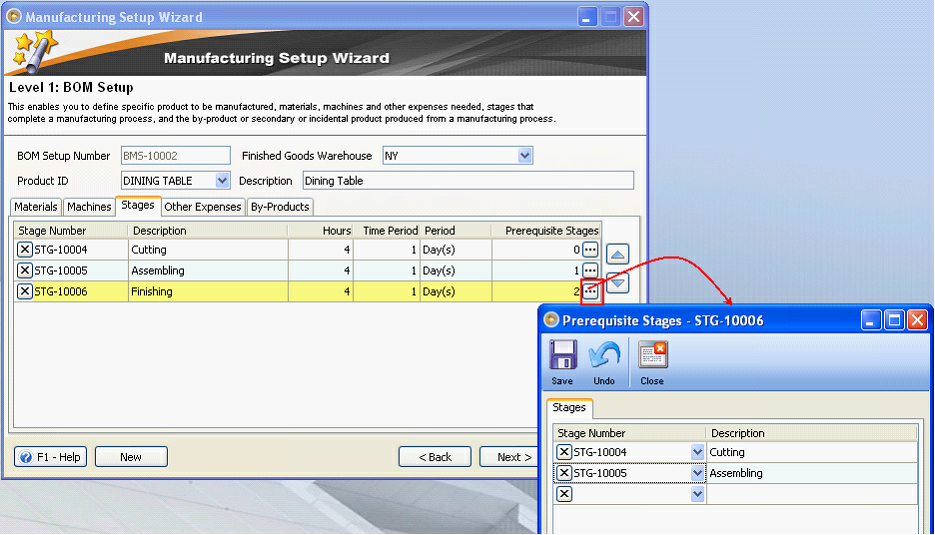

Stage setup

The Stage tab is used to add stages that complete the production process.

How stages are setup:

Click on the New button at the bottom left of the form to create a new stage

In the Prerequisite Stage field, click the ellipse button to assign prerequisite stage/s to a certain stage. Prerequisite Stages form will list all stages prior to the selected stage and it is on this form where you can configure what stages must be completed prior to completing the said stage.

So in Assembling Stage, Cutting stage must be completed first before the said stage can start.

In Finishing Stage, Cutting and Assembling stages must be completed first before the said stage can start.

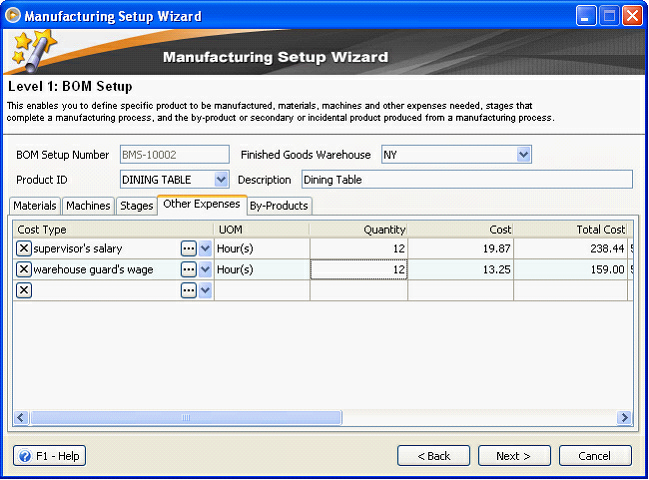

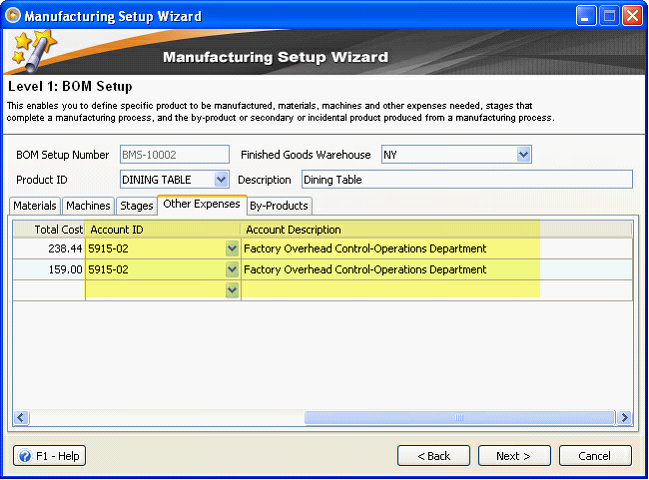

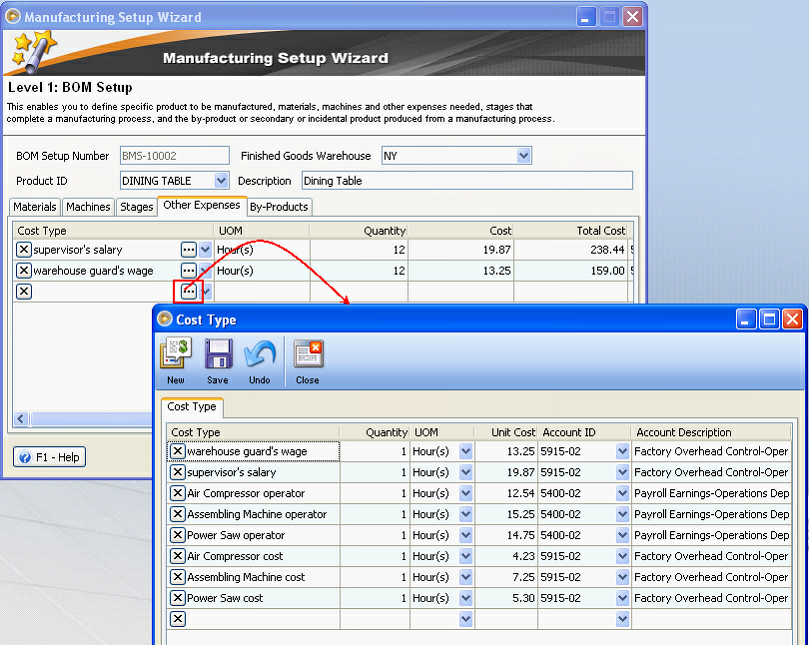

Other Expenses setup

The Other Expenses tab is used to add other expenses directly or indirectly related in manufacturing the product.

Use the scroll bar to configure accounts to be used.

How other expenses are setup:

Click the ellipse button on Cost type field to open the Cost Type form where you can add other cost types.

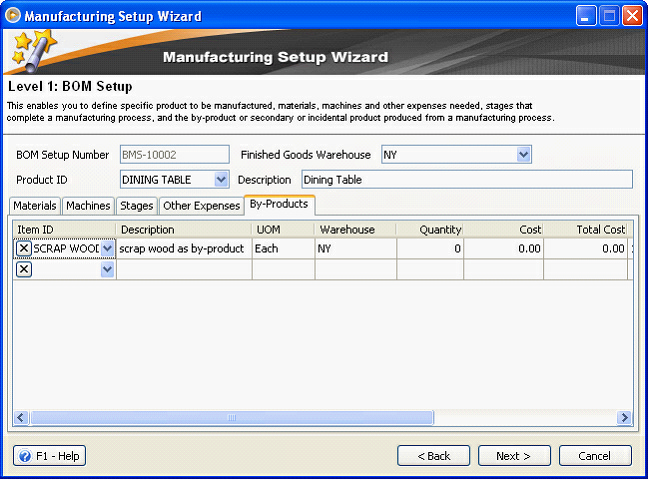

By-Products setup

The By-Products tab is used to enter secondary or additional product produced in the course of manufacturing the primary/main product.

When you are through with the above setup, click Next button to move to the next level > Level 2: Stage Details.